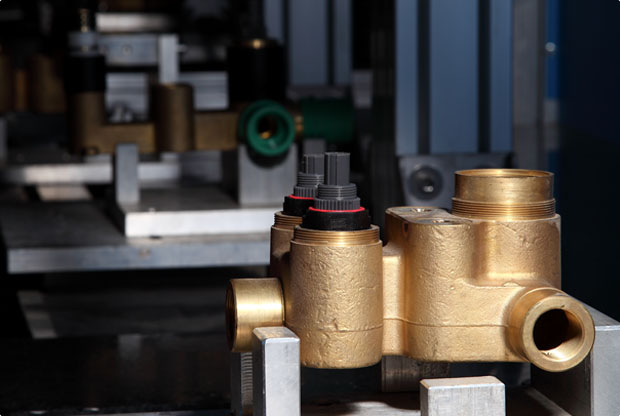

INNOVATION

Infused with Dinggu's belief into innovation products. Following the mainstream market

and also with Dinggu’s special characters. Flooded Dinggu’s element in the bathroom market.

and also with Dinggu’s special characters. Flooded Dinggu’s element in the bathroom market.